top of page

Business

Process Planning & Management

Respond quickly to rapidly changing situations through on-site situations

and work leading, and set a clear target process rate to achieve plan progress.

By efficiently managing resources we achieve the best results

while adhering to project schedules and budgets.

Perform smart process management

for smooth communication between participants

Site monitoring &

Catch-up Plan

Integrated management

of cost schedules

+

BIM-4D process management

+

Established rate-to-process rate management unification

Simulate multiple

process plans

Construction period delay prediction and recovery measures established

Calculate objectified process data

and perform centralizedmanagement

with PMS settings agreed

between participants

Verification of construction period

achievement by performing multiple digital

twin-based simulations in conjunction with

the network schedule (conduct daily review)

Process trend prediction based on real-time monitoring of progress data and

on-site changes and recovery measures

to construction period delay established

01

PMS setting

Set a unified standard among participants

An agreed PMS between project participants is set for objective process rate calculation and accurate claim. It manages the process rate and the established rate in a unified manner by setting objective standards based on Sodur. The use of the same barometer induces smooth communication between the client and the participants.

02

Ensuring the consistency of the process plan

Ensuring the consistency of the process plan

A network schedule is prepared in consideration of various complex construction and process relationships during the project. The relationship between the pre- and post-process is analyzed, and the impact of unit construction and all construction period according to the activity is reviewed simultaneously. The feasibility of construction period is improved by reflecting the real productivity of the construction company and its suppliers.

03

Daily 4D review

Visualization management of the process plan

Establish a 4D simulation by linking the network schedule and BIM. The process plan and construction period achievement are verified daily by process simulation reflecting the construction plan and major construction methods. Implement the digital twin of "BIM= site" agreement by continuous site monitoring and immediate reflection of changes, and perform the construction simulation according to the changed construction plan. Construction period delay risk is visualized and provided to project participants through the interference of the complex process and the comparative review of Plan vs Actual.

04

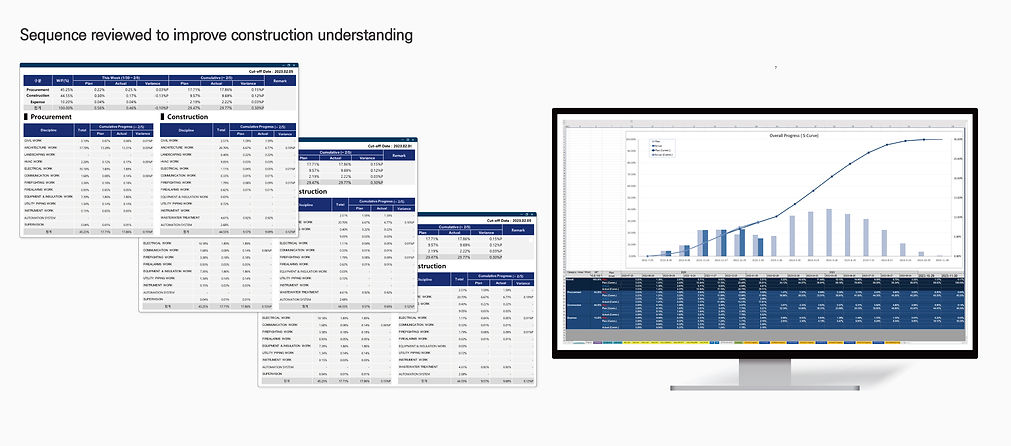

Progress-based performance management

Ready rate = performance management of process rate matching

S-curve achievement management is performed based on the received disclosure performance details data for each type of construction. Through a preset PMS, the representative quantity for each type of construction becomes the basis for calculating the established rate, and the established rate calculated in this way becomes the process rate. The S-curve performance data consistent with "Establishment Rate = process Rate" is used as basic data for weekly/monthly trend analysis.

05

Construction period delay prediction and recovery measures established

Contributing to the improvement of construction period achievement rate in the field

It analyzes weekly/monthly trends based on the progress S-curve. Based on the planning schedule and performance data, the construction period ‘Ahead and Behind’ are discriminated, and the future process trends are predicted by comparing and reviewing the expected construction volume and the executable volume in the future. The construction period delay risk derived during trend analysis is immediately issue to project participants.

06

Etablish catch-up plan

Quick suggestion for construction period delay recovery measures

A quick countermeasure is proposed by analyzing milestones in the event of an construction period delay and finding countermeasures for each construction period delay issue. Recovery measures are established through additional input and readjustment of major resources such as operation rate improvement, manpower, and equipment, and changes in construction methods and construction sequences, and each established countermeasure is verified by construction period recalculation. Scenarios for each construction period delay situation are established in advance with each recovery measure if necessary.

bottom of page